Published on Show Me Mizzou Sept. 17, 2025

Story by Dale Smith, BJ ’88

Photos by Abbie Lankitus

Every year, contractors in the United States lay nearly 500 million tons of asphalt pavement. That’s enough to cover a two-lane road from New York to Los Angeles and back 20 times over. Hot, black and endlessly flowing, the asphalt migration is among the most massive material movements on the planet. Another mass movement? Waste. Americans toss out roughly one tire per person annually and more than 35 million tons of plastics, including the grocery bags, thin wrap and lightweight bottles that pile up in bins or end up in landfills.

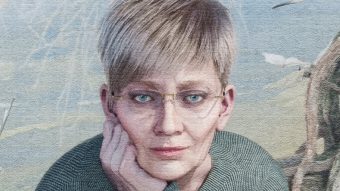

Punya Rath, PhD ’20, oversees research at the Missouri Asphalt Pavement and Innovation Lab (MAPIL) at the University of Missouri. He describes such waste as “a huge mover of raw materials,” explaining that most discarded plastics and tires are polymers — which happen to be the same broad class of materials engineers use to strengthen asphalt mixtures.

“We’ve worked toward replacing the virgin polymer with ground tire rubber and waste plastics that would otherwise end up in landfills,” Rath says, noting the lab’s philosophy of using finite materials judiciously and exploring “new ways of doing things that are not harming the planet.”

Rath’s mentor and colleague, MAPIL Director Bill Buttlar, is a leading pavement engineer and Glen Barton Chair in Flexible Pavements at Mizzou's College of Engineering. Buttlar’s students know him as an award-winning teacher and guide. He shapes pavement practices worldwide through his research and organizational leadership, including at the International Journal of Road Materials and Pavement Design, where he is editor in chief at large. Under his leadership, MAPIL’s efforts range from developing sustainable materials and regional supply chains to testing, field trials and performance evaluations that support smarter road design and maintenance.

Rewriting the recipe for the road

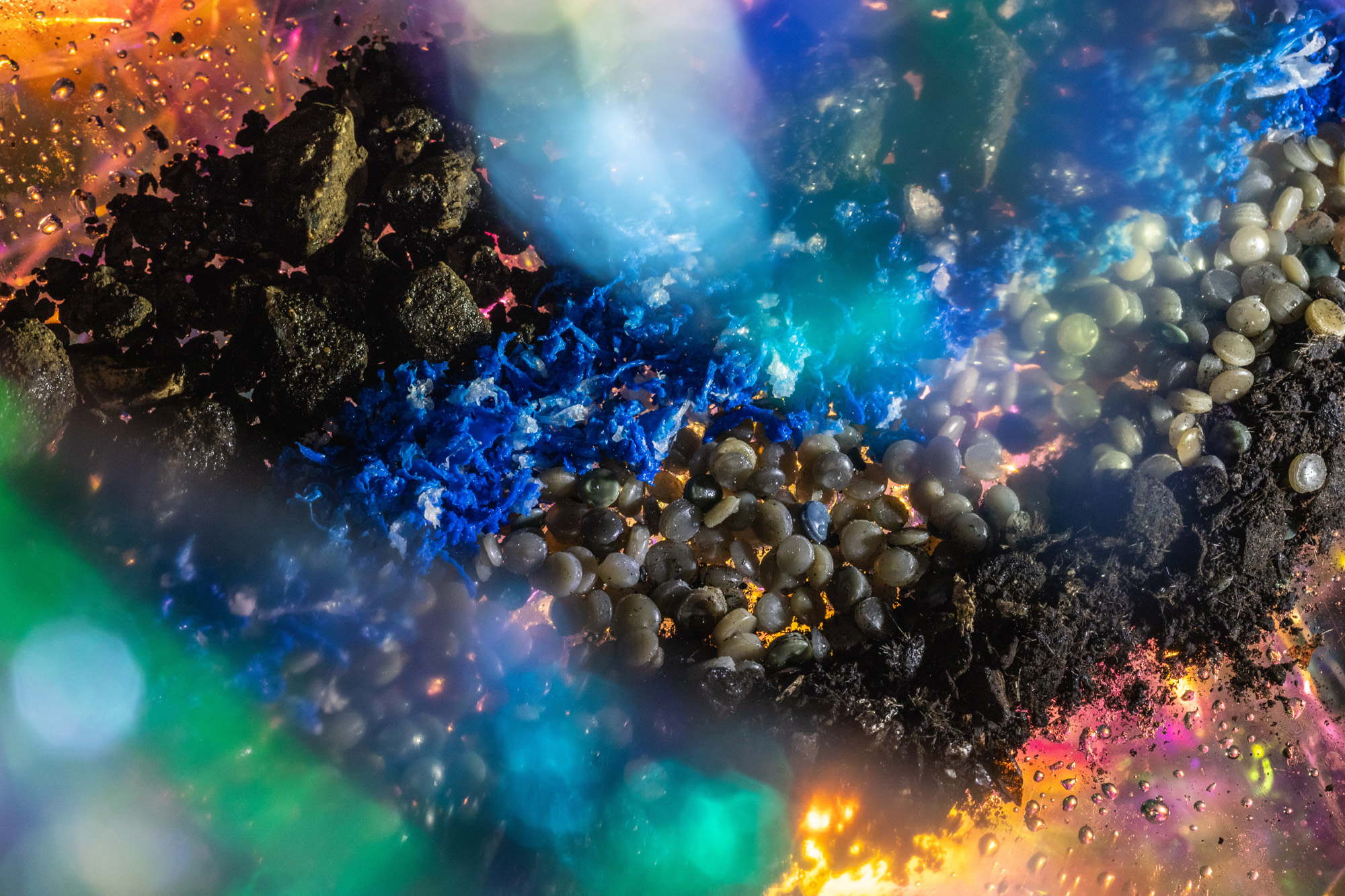

The dark layer atop our roads consists of two main ingredients: Inexpensive and plentiful rock, referred to as aggregate, makes up about 95% by weight. The characteristic black binder is the costlier part. Asphalt, a thick and sticky byproduct of gas and oil production, glues the gravel together, but making a durable pavement requires additional ingredients. Depending on how engineers design the recipe, additives contribute to the pavement’s critical characteristics. Chief among them is resistance to forming ruts in the heat of summer and cracks in winter’s brittle cold.

Asphalt binder is made at regional terminals, where it’s blended in large, heated tanks, then trucked to asphalt plants for mixing with aggregate. Recycled materials such as plastic or rubber can be added in two ways: at the terminal with the binder (wet process) or at the plant with the aggregate (dry process).

MAPIL has advanced the dry method, which allows contractors to add recycled material directly to hot aggregate before the binder goes in. It’s often cheaper and easier to manage. “Dry process is simpler logistically and generally cheaper,” Rath says. “It’s a low-bid industry, so dry process usually wins the job.” Much of the lab’s output focuses on helping contractors do better, more affordable and more sustainable work.

The afterlife of everyday things

Recycling tires as a binder additive has been around since the 1960s. It fell from favor in the 1990s but has been making a comeback over the past decade or so, partly because of the dry process technology that MAPIL advocates, Rath says. Rubber suppliers remove the steel belts from old tires, then grind them into sand-sized particles and add a coating that helps the material combine with asphalt binder. One plant dedicated to this process recently opened in Springfield, Missouri.

Although tire rubber wears down somewhat after thousands of miles on the road, it remains a tough, durable material, Buttlar says. “When we add it to the hot gravel, now it has this really sturdy ingredient that reconstitutes, so we get more adhesive and a tougher adhesive.” Beyond that, rubber creates a smooth-riding surface that is far more durable than traditional blends. Buttlar says pavement has a 15- to 20-year life cycle before requiring substantial maintenance, typically, but rubberized pavements can last twice as long before cracks and potholes need tending. That saves the governments that maintain the roads, and ultimately the taxpayers, money.

Waste-stream polyethylene plastic, which flows from plentiful sources — including hundreds of millions of grocery bags a year — has long seemed a natural choice to become the next big binder additive. It resists summer rutting well but is prone to cracking in winter. Helmut

Leodarta, a MAPIL doctoral student with expertise in chemical engineering, tackled the problem. “It needed another ingredient,” Buttlar says, “so we looked at soybean oils that were not food grade but perfect for industrial uses.”

Missouri is a big soybean producer, so the oil was handy. The supply chain for plastic, however, is still evolving. While Leodarta was doing his research, Buttlar got a tour of Aurora Organic Dairy in north Columbia. His son, Josh, BS BA ’23, is on Aurora’s management team.

Buttlar quickly discovered the plant sent its waste plastic to the landfill, so he pitched the idea of collecting and recycling it into local roads. Now the lab has developed a process (and a patent-pending technology tentatively called Tiger Plas) to create blocks of plastic that are ground and incorporated into binder. Buttlar points out the closed-loop efficiency of transforming inexpensive local waste into Missouri roads. Lab results for the longevity of plastic are comparable to rubber, but plastic is far more plentiful, Buttlar says. “In a process similar to that used for rubber, let’s add recycled plastic to the asphalt mixture to save cost and divert waste from landfills while lengthening the roadway’s life. If we can stretch our money this way, maybe we can improve more infrastructure than we would otherwise.”

There’s no time to lose, he says. Even with less costly, higher performing pavements, fixing a massive network of roads could take a generation.

Standards written in stone and tar

The Missouri Department of Transportation (MODOT) typically spends up to five years evaluating new pavements before issuing specifications for contractors. “The proof is in the pudding,” Rath says, pointing to real-world tests on neighborhood streets in Kansas City and on MODOT projects along Columbia’s Stadium Boulevard and I-155 near Hayti, Missouri.

Jen Harper, BS CIE, ’99, MODOT’s research director, says these early-stage projects look promising. When her department needs information, MAPIL is one of only three labs in the state that can offer research-based answers. She adds that Mizzou’s expertise includes not only asphalt through MAPIL but also traffic, safety and hydrology elsewhere in the College of Engineering.

She likes that MAPIL’s approach considers both cost and sustainability. “MODOT has a strong interest in environmental responsibility that also helps make Missouri’s tax dollars go farther,” Harper says. “It appears we may be able to recycle plastic in asphalt binders. That’s attractive, and I hope we will be able to develop a specification contractors can use for this.”

Evaluating the success of new approaches has long meant sending people out to eyeball roads, score their condition and theorize about reasons for degradation. The possibility for human error is substantial.

One of Buttlar’s students, Hamed Majidifard, PhD ’21, set out to harness the ability of artificial intelligence to recognize patterns and details — anything from faces of people in an airport to power poles along the side of a road. Majidifard and the lab developed a suitcase-sized system (and a spinoff company called Tiger Eye Engineering) that can be attached to an SUV as its camera charts cracks, ruts, holes and other flaws it drives over.

Tiger Eye’s AI measures road flaws against international standards and presents the results for review. “The data create heat maps of problems,” Buttlar says. “Green means the road is nearly perfect. Red represents more severe cracking and rutting, and there’s yellow and orange in between.”

Engineers like to review individual sections — sometimes even frame by frame. “You could locate every pothole in a city or spot all of the cracks,” he says. The data also feed into sophisticated software for asset management, planning and budgeting. It greatly accelerates the process of evaluating roads and deciding what to do next.

Beyond serving the lab’s projects, Tiger Eye has clients across the U.S. and Canada. It also helps test new materials and building methods, Buttlar says. How does asphalt hold up compared to concrete? How thick a layer of pavement best balances cost and durability? Can contractors maintain quality when adding wax or other ‘warm mix’ compounds to the binder to lower the heat required, as well as emissions of volatile organic compounds?

MAPIL’s research philosophy blends innovation with real-world demand. To better understand what industry wants, lab members complete a seven-week National Science Foundation course on testing market interest and shaping ideas to fit. In 2022, the Tiger Eye team won its class in the competition.

Building minds, not just roads

Buttlar leads with more than four decades of know-how, but it’s his approach to bringing along young engineers that expands and perpetuates the lab’s accomplishments. Buttlar jokes that, as a student at Penn State in the 1980s, “I didn’t know what I wanted to do when I grew up.” He started in nuclear engineering, then realized he preferred physics over chemistry and pivoted to civil engineering.

That early shift informs how he mentors graduate students. “I’m receptive to them trying out various directions to discover where their interests and abilities lie.” He often forms teams of students who take on various roles as they identify real-world problems, write proposals for possible solutions, seek funding, analyze markets and test ideas in the field.

Creativity is a central feature at MAPIL, Buttlar says: “Engineers are by nature clever. They want to tear open the radio, tinker around and fix it.” But when the answer is unclear, it can be difficult to see the next step. The master has a deft touch at such moments, says Rath, who began studying under Buttlar a decade ago at the University of Illinois. “If you ask him about a problem, he can talk you through 20 ways to solve it. But he doesn’t micromanage. He gives you the creative freedom to figure things out yourself. That’s the only way you can develop your own style.”Sometimes, Buttlar’s job is to help young engineers recognize subtler forms of progress. “We need to keep our chin up while we innovate and take joy in the null hypothesis,” he says, referring to a test that shows nothing new. “That’s a dead end you just closed.”

The road ahead will demand more of these insights. For instance, take platooning: automated truck convoys that save fuel but strain pavement. With less time to recover between loads, today’s binders won’t hold up against it.

Buttlar isn’t worried, and he’s certainly not about to retire. “I’ve got plenty of fuel left in the tank, and there are too many problems.” What’s more, he says, his field is developing in exciting ways. Rather than looking at individual components, “We are starting to engineer whole systems. And AI is offering exciting possibilities. The pace of discovery is increasing rapidly.”

To read more articles like this, become a Mizzou Alumni Association member and receive MIZZOU magazine in your mailbox. Click here to join.