Sept. 3, 2025

Contact: Brian Consiglio, consigliob@missouri.edu

Photos by Yvonne Groner

Researchers at the University of Missouri are working to make hydrogen energy as safe as possible.

As more countries and industries invest heavily in cleaner, renewable energy, hydrogen-powered factories and vehicles are gaining in popularity.

But hydrogen fuel comes with risks — leaks can lead to explosions, accidents and environmental harm.

Most hydrogen-detecting sensors on the market are expensive, can’t operate continuously and aren’t sensitive enough to detect tiny leaks quickly.

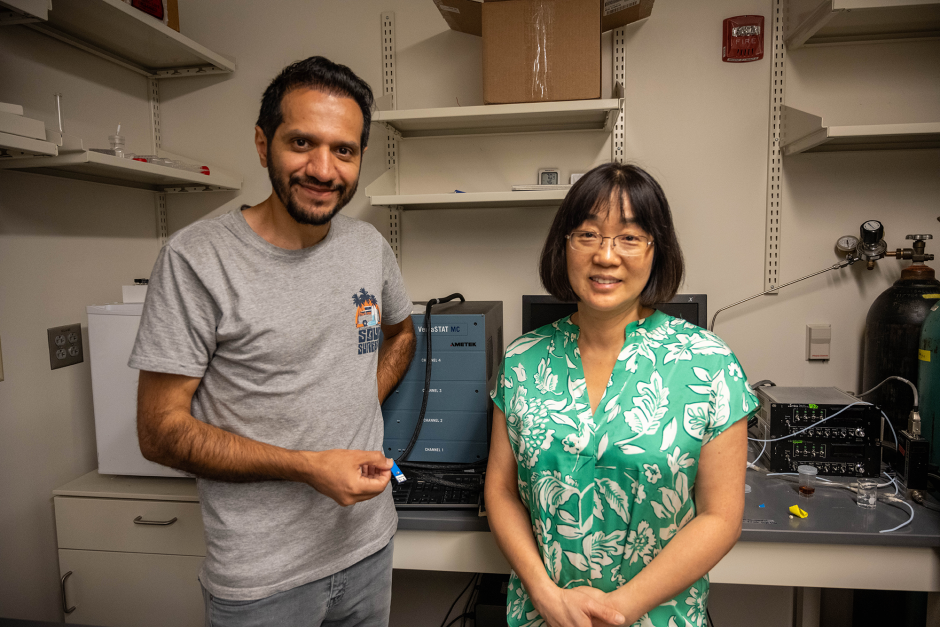

That’s why Mizzou’s Xiangqun Zeng and her team in the College of Engineering set out to design the ideal hydrogen sensor, focusing on six traits: sensitivity, selectivity, speed, stability, size and cost.

In a recent study, they unveiled a prototype of an affordable, longer-lasting, super-sensitive sensor that can accurately detect even the tiniest hydrogen leaks within seconds. The best part? It’s incredibly small, measuring about the size of a fingernail.

Zeng created her sensor by mixing tiny crystals made of platinum and nickel with ionic liquids. Compared to what’s already on the market, the new sensor is unmatched in performance and durability.

“Hydrogen can be tricky to detect since you can’t see it, smell it or taste it,” said Zeng, a MizzouForward hire who creates sensors to protect the health of people and the environment. “In general, our goal is to create sensors that are smaller, more affordable, highly sensitive and work continuously in real time.”

While her new hydrogen sensor is still being tested in the lab, Zeng hopes to commercialize it by 2027. Mizzou is committed to furthering this impactful research, as prioritizing renewable energy will be a cornerstone of the new Energy Innovation Center, expected to open on Mizzou’s campus in 2028.

Creating improved sensors with broad applications in health care, energy and the environment has been Zeng’s mission throughout her career, and her work has been heavily funded by the United States Department of Energy, the National Institutes of Health, the National Science Foundation and the Office of Naval Research.

“My expertise is in developing next-generation measurement technology, and for more than 30 years, I have prioritized projects that can make the biggest impacts on society,” said Zeng, who also has an appointment in the College of Arts and Science. “If we are going to develop sensors that can detect explosive gases, it needs to be done in real time so we can help people stay as safe as possible.”

“PtNi nanocrystal-ionic liquid interfaces: An innovative platform for high-performance and reliable H2 detection” was published in ACS Sensors.