Aug. 16, 2023

Contact: Eric Stann, 573-882-3346, StannE@missouri.edu

Transformational changes are already underway in the manufacturing industry as technological advancements, such as artificial intelligence (AI) and smart devices from the “fourth industrial revolution” or Industry 4.0., inspire a digital-first approach to engineering.

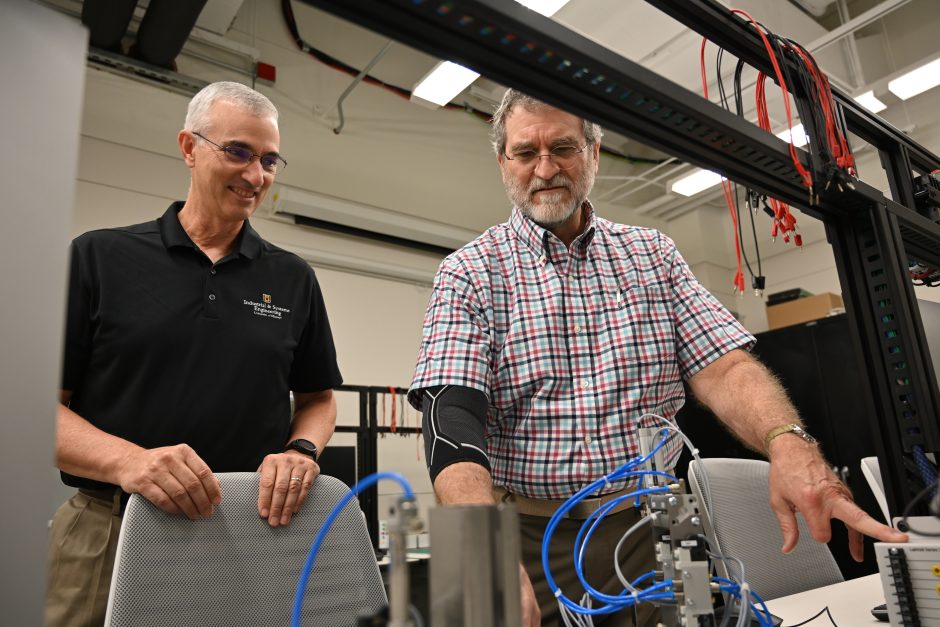

Now, University of Missouri researchers Jim Noble and Yi Wang are using a one-year, $1 million grant from the Missouri Department of Higher Education and Workforce Development to create hands-on learning experiences in an Industry 4.0 lab to help future engineers thrive in the latest industrial revolution’s technology-centered job market. MU’s Industry 4.0 lab, located in the College of Engineering, is scheduled to open in fall 2024.

“Industry 4.0 is multi-faceted, but at its core, it’s a fusion of information — cyber security, big data, cloud computing and blockchain — and cyber-physical manufacturing — sensors and Internet of Things (IoT), additive manufacturing, robotics, collaborative robots, autonomous material flow and digital twins,” said Noble, professor and chair of the Department of Industrial and Systems Engineering. “Our Industry 4.0 lab will be a showcase of how all these aspects fit together seamlessly.”

The college’s two existing manufacturing core labs — one focused on integrated industrial controls and automation and the other focused on a combination of traditional and advanced manufacturing — will provide undergraduate students with the foundational skillset needed for working in the Industry 4.0 lab.

“The Industry 4.0 lab gives us the ability to integrate skills at a higher level and the capabilities to continually keep students at the state-of-the-art level for industry,” Noble said. “It’s what industry is already starting to do.”

Part of the grant includes the development of courses for a potential undergraduate student certificate, as well as an extension certificate that people in the industry can use for training purposes. The lab’s curriculum development will be supported by an industrial advisory board, including 3M, Gates Corporation, Hubbell Power Systems, Rockwell Automation and Tri Tech Automation.

“There are some industries in Missouri that are moving toward greater integration and digitization, but there’s still a lot that haven’t yet. So, we want them to come to us and let us train them to be thought leaders as they go back and work in their companies,” Noble said. “That also applies to our students as well. We want to give them the foundation to be able to be leaders of this latest industrial revolution, or Industry 4.0.”

Editor’s Note:

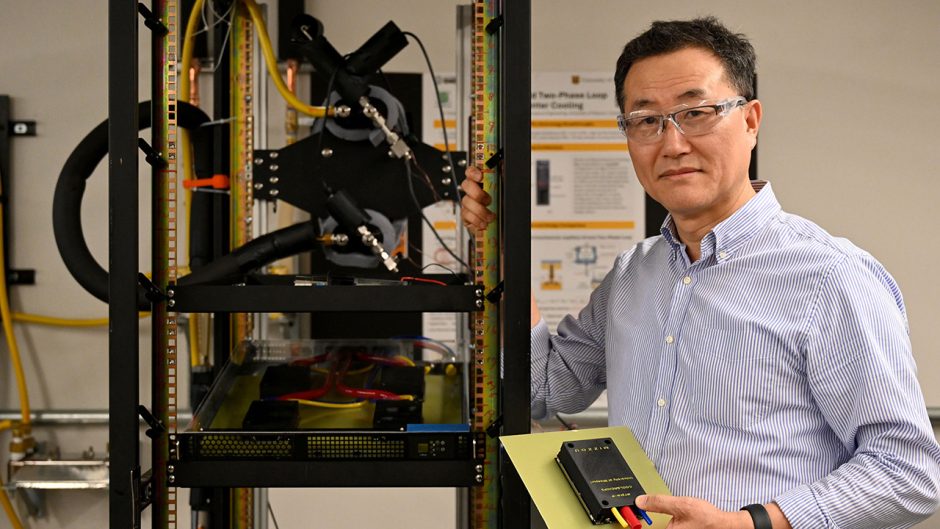

Wang is an assistant professor in the Department of Industrial and Systems Engineering.